Virtually all LJR Studio creations begin their lives as a spool of metal wire. The first step requires what is called “tempering” the wire. Tempering alters the molecular structure of the metal. Through heat treatment and cooling, the crystal structure is disrupted. This process makes the wire sufficiently pliable, allowing it to wrap tightly around a specific diameter of polished steel rod (a mandrel) to create a spring whose inner diameter is slightly larger than the diameter of the rod. The inner diameter is slightly larger only because the process of wrapping somewhat hardens the wire, causing a slight springiness when removed from the rod.

The diameter of the wire chosen determines the “weave” of the chain created from the springs. Each particular metal and weave creates a different appearance of the chain and is controlled by the ratio of the inner diameter of the spring to the outer diameter of the wire, known as the AR Ratio.

The second step in creating these articles involves using a jeweler’s saw to cut through the spring, creating a slightly open metal ring for each turn around the mandrel. These rings are then woven together creating the patterned chain. Some of the creations use several different metals for contrast and effect and some even employ several different diameters of ring and/or wire, depending on complexity.

Some of the wire used is created from textured wire for special effects, such as a sparkle or series of small beads connected together into wire.

When very small rings are woven into a tight weave, the strength of the metal is sufficient to prevent the rings from opening with use. Larger rings and smaller diameter wire patterns are hand soldered with metal matching the wire rings to prevent opening with normal wear.

In addition to traditional wire, which is round in cross section, innovative suppliers have created wire with additional cross sections, such as square, rectangular or flat, triangular and half-round. Half-round wire is particularly useful in creating a spiral woven chain that will not untwist when opening the closure. Though slightly more expensive to produce, due to the added labor in handling several small individual rings, this can offer a great convenience in wearing the resulting product.

Since all hand crafted products can be made to order, in addition to choice of metal, clasp or closure and size, you are free to choose, within reason, almost any design you can imagine! This makes you the creator and designer of your own unique piece and our artist, merely the instrument by which it is manufactured!

All creations are hand crafted from metal wire or sheet, whether silver, gold or brass. LJR Studio prefers working in gold and silver. They are more easily formed than most metals.

Unless described as fine silver, which is at least 99% pure silver, LJR Studio uses sterling silver, an alloy with copper and other minor constituents. Sterling silver is 92.5% silver with the balance of the alloy predominantly copper. Sterling silver will tarnish if not used regularly. This phenomenon is caused by exposure to air and its contaminants. Tarnish can be easily removed with commonly available silver polish or by using a Sunshine® Polishing Cloth. Our artist wears his sterling silver bracelets continuously, never removing, and it has never tarnished. If not worn constantly, one may prevent tarnish with careful storage of sterling silver in specially treated Silver Cloth. Fine Silver is much more resistant to oxygen and other contaminants in air. Unfortunately, though requiring little care in storage, fine silver is much softer than sterling silver and is therefore less robust and subject to mechanical damage. Consequently, fine silver is rarely employed in jewelry except for decorative embellishments. LJR Studio occasionally employs fine silver wire where it is desirable to avoid the use of solder to connect pieces. Fine silver will fuse to itself, eliminating the use of solder.

Each of gold chain creation is handcrafted from 14K gold filled wire, wound tightly by hand on a mandrel, typically round in cross section, to create a long spiral spring with an inside diameter equal to the diameter of the mandrel. The spring is subsequently sawn with a fine jeweler’s saw to produce individual rings. The rings, once separated from the spiral, are then woven by hand into one of many different interesting weaves. Many of these weaves are commonly available in machine manufactured bulk chain which fails to exhibit the character and beauty of handcrafted articles. Gold fill wire is essentially a solid gold tube mechanically bonded to an inner base metal core. Also known as gold overlay, gold filled wire is a great option for making precious gold jewelry without the cost of solid gold. Gold fill is created by using heat and pressure to apply a layer of karat gold to a base of less costly metal. The artist uses only 14K gold equal to 5% of the total wire weight. This allows LJR Studio to sell hand crafted creations for as much as 90% less than the price for solid gold pieces. High quality gold-filled pieces have the same appearance as high karat gold, and gold-filled items, even with daily wear, can easily last 10 to 30 years though the layer of gold may eventually wear off exposing the metal underneath. In our artist's experience, he has never actually experienced such extensive wear.

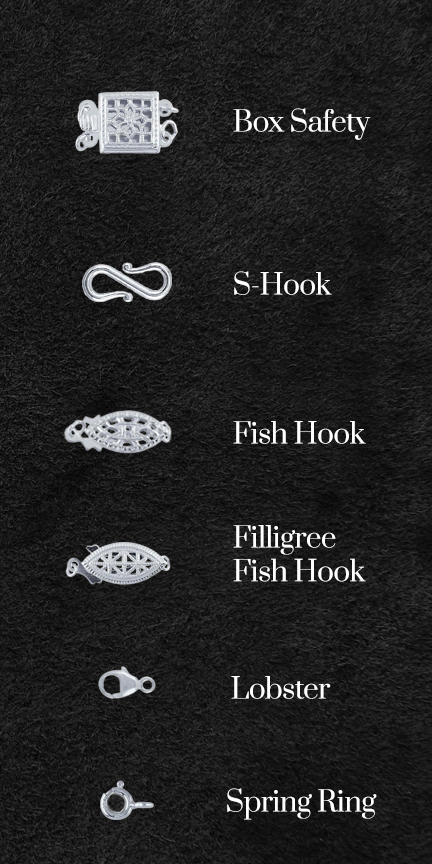

Browse our custom clasps.